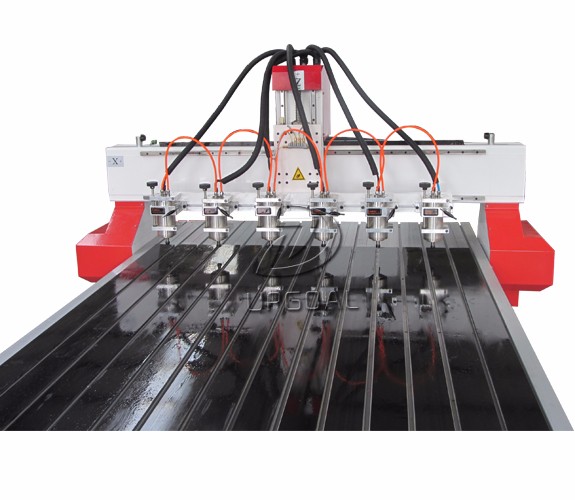

Brief Introduction:

Model: UG-1318-6

1300*1800mm working area

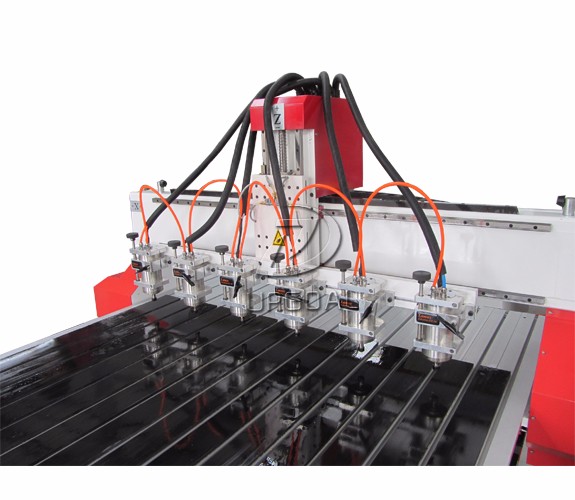

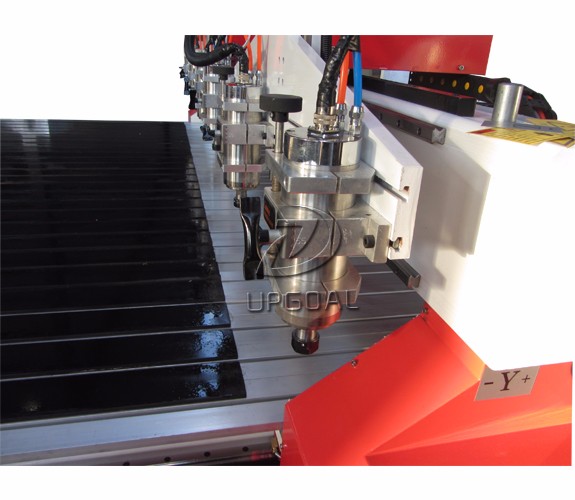

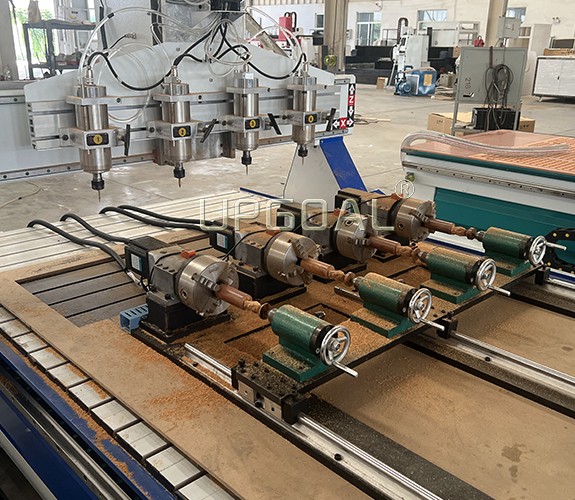

6 spindles on one Z-axis

DSP offline control system

Panasonic Japan servo motor and driver

Applications

Woodworking products, advertising signs, MDF board, cutting engraving Photo frame, sculpture the sofa and the head of a bed, All kinds of wood door carvings, Large furniture relief engraving, Dalle hollow out and simple copper aluminum plastic board, etc.

Features

1.Welded steel T type structure as a whole with vibration Temper aging treatment ensures no deformation for long time.Cast iron Gantry, the structure is strong and stable.

2. Imported Hiwin, Taiwan Linear square guide rail with ball bearing slide block which ensure high weight capacity, high precision, smooth and steady running. Adpot imported precision ball screws, tools feeded with more accuracy.

3.2.2KW water cooling spindle which is with stable performance, low noise and high torque, matched with high-performance Frequency Inverter. 6 pcs on one Z-axis structure, each time can process 6 same items, improving the efficiency.

4.Japan Panasonic servo motor and driver for XYZ-axis, high precision, fast speed and more stable, dual motor Driven Y axis with traveling speed up to more than 25000mm/min.

5. Helical gears Pinion with Racks type transmission for X and Y axis, higher running speed and efficiency, saving cost. Z- axis with precision ball screw, high precision and more durable.

6.DSP offline control system with USB interface which is completely off from Computer. More Humanized design with Simple and Convenient Handle type operation.With pre-calculation rule, fully excavating potentialities of motors. Enable high processing speed, synchronization of Curve and straight line, more perfect curve working and Spindle startup and stop automatically.

7.Semi-auto lubrication system more convenient for maintenance.

8. Favorable compatibility with various CAM softwares such as Type3/Artcam/Mastercam/Caxa. With intelligent over limit protection function which can stop the mechanical collision due to unproper size given to the design.

9. With the function of Break-point memory,power failure resuming and automatic home/origin correction function, effectively ensure long time working precision.

Effective working area | 1300(X)mm*1800(Y)mm*200(Z)mm |

Materials | More thickness steel pipe welded machine holder bed, cast iron gantry |

Working table | Aluminum T slot working table |

Moving type | Gantry moving |

Guide rail | Linear square guide rail ( Hiwin, Taiwan) |

Transmission | Helical rack &pinion for X Y -axis, Lead ball screw for Z-axis |

Driving mode | Panasonic Japan servo motor and driver for XYZ-axis |

Spindle motor | 2.2kw water cooling, 6pcs |

Spindle speed | 0-24000rpm |

Inverter | Delta, Taiwan |

Voltage | AC 220V+ 10%, 50/60Hz, single phase or AC 380V+ 10%, 50/60Hz, three phases |

Traveling speed | >25000mm/min |

Engraving speed | >12000mm/min |

Machine accuracy | 0.01mm |

Control system | DSP offline control system |

Suitable software | Artcam, Type3, Ucancam V9,etc |

Carving Instructions | G code *Uoo *mmg *plt HPGL |

Running environment temperature | 0-45 ℃ |

Relative humidity | 30%-75% |

Lubrication system | Semi-auto |

Tool calibration | Auto |

Certificate | CE |